User: CCCC Highway Bridges National Engineering Research Center Co., Ltd.

According to the existing laboratory space of CCCC Highway Bridges National Engineering Research Center, POPWIL designed the bridge foundation three-way static and dynamic testing platform, and realized the static and dynamic loading test for the research and the test demand of foundation and pile integrated sample. This project has won the first prize of CCCC technology invention.

Basic Functions:

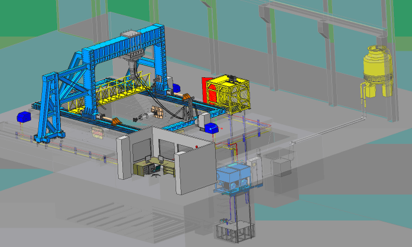

The three-way static and dynamic testing platform is composed of model box, four side reaction walls integrated with the model box, movable loading frame installed on the reaction wall, electro-hydraulic servo multi-channel loading system, water level control system and data acquisition system. Which is used to do the mechanical performance test of the interaction between bridge foundation pit or pit with the upper construction and foundation soil in the laboratory.

The 3D drawing of the design and the onsite photo are as follows:

The 3D drawing of the testing platform

The onsite photo of the testing platform

Basic Parameters:

- Size of model box (length*width*depth) : 10 * 6 *8 meter

- Vertical actuator

Maximum dynamic load: 2,000kN;

Maximum working frequency: 15Hz;

Fixed on a two-way follow-up sliding plate. - Horizontal actuator

Maximum dynamic Load: 200kN;

Maximum working frequency: 15Hz;

Can be installed at any suitable place of the side reaction wall. - The loading position on the vertical loading frame can be adjusted together with the frame on the top of the reaction wall along the long side;

- The horizontal loading actuator can be arranged around the reaction wall at the upper part of the model box;

- The computer-electro-hydraulic servo control system and software can control 5 actuators to complete static and dynamic loading at the same time.