1. Controller

Popwil's geotechnical engineering testing system also uses POP-M multi-channel controller. The controller is a pure digital controller. It has a full size I-PC, a connecting box with signal and power amplifier, and several AD and I/O cards. Together with LCD, keyboard and mouse, the special test software under the Windows operating system controls the surface load actuators to complete the geotechnical test.

Due to the particularity of the geotechnical engineering test system, Popwil has developed a PLC-based POP-SR controller that can work under the control of a POP-M controller or work offline and independently.

- The POP-M controller is the main controller. If required by the test, it can be connected to the POP-SR long-term load retention controller, and the longest surface load retention time can reach 1 year.

- Each POP-M controller has 8 output channels. Each POP-SR controller can control up to 8 surface loads. There are two solutions for more than 8 channels: customization or using two POP-M (two POP-SR controllers) controllers connected through the network.

- Each channel of the POP-M controller has two 16-bit AD inputs, one 12-bit DA output, four I / O signal interfaces, and one SSI signal interface for magnetostrictive displacement sensor signal input.

- The POP-SR controller outputs are digital outputs. Usually in the beginning of control, it needs to work with POP-M controller.

- The sampling frequency of each AD of the POP-M controller is 1kHz. Each DA output can realize 200Hz PID closed-loop control, and the closed-loop adjustment frequency can reach 1kHz when special needs.

POP-M controller with desk

POP-M controller applied to geotechnical engineering test system

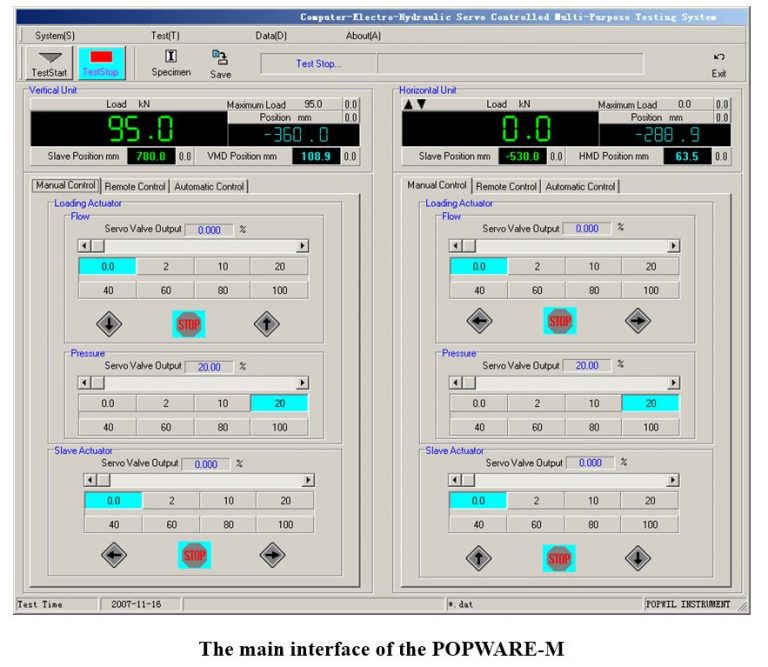

2. POPWARE-M Software

The operating software of the POP-M controller is called POPWARE-M。It was developed by Popwil in 2004, worked under Windows 98, and the first copy was sold to Tongji University - famous for her Civil Engineering College in China. Since then, the software is under improving continuously. The most recent copy of the POPWARE-M can control as many as 128 actuators separately and simultaneously under Windows 10. The operator can control a test and make data acquisition by simply click the mouse.

In addition, users can also customize special versions to meet individual requirements according to their own special needs, which truly meets the personalized customization requirements of multifunctional test systems. The specially customized software omits the complicated professional operations such as complex software initial settings and control channel settings, has a dedicated operation interface and operation sequence, simplifies the learning and training process, and improves the reliability and operability of the equipment.

The main interface of the POPWARE-M shows bellow.