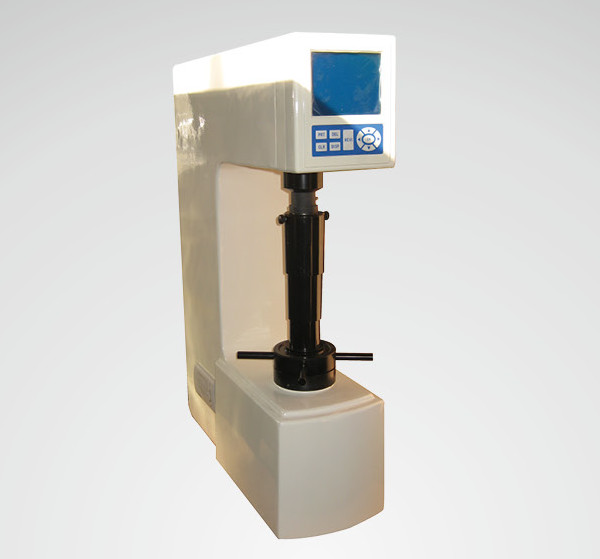

HRS-150A Digital Display Manual Rockwell Hardness Tester

HRS-150A Digital Display Manual Operating Rockwell Hardness Tester

Main Function

- The latest digital liquid crystal display, button battery powered, easy maintenance.

- Ultra-low power consumption, long battery life, up to one year of normal use.

- No external power required.

- Manual loading-hold-unloading, simple operation.

- Automatic hardness display with high accuracy, no artificial reading error.

- The displayer has a digital output connecter. An external mini printer is optional.

- Printed report content: hardness average, maximum and minimum, hardness dispersion.

- With automatic conversion with other hardness such as HB, HV, etc.

Application

- To determine the Rockwell hardness of ferrous metal, non-ferrous metal, and other materials.

- It’s mainly used for Rockwell hardness measurement of heat-treated materials.

- To determine the surface Rockwell hardness of ferrous metals, alloy steels, hard alloys and other metals after surface treatment.

Specifications:

Hardness scale |

A, B, C, D, E, F, G, H, K |

Test force |

kfg: 60, 100, 150 N: 588, 980, 1471 |

Test Range |

20~88HRA, 20~70HRC, 20~100HRB |

Indicative resolution |

0.1HR |

Indication accuracy |

Meet GB / T 230.2, IS0 6508, ASTM E18 standards |

Test force holding time |

1-99 seconds adjustable |

Maximum specimen height |

195mm |

Distance from indenter center to machine wall |

140mm |

Power |

220V/50-60HZ |

Dimensions |

Length * width * height 463 * 175 * 660mm |

Weight |

Net weight: 74kg, gross weight: 90kg |

Touch screen display content |

Hardness value, Rockwell scale, total test force, holding time, field temperature, upper and lower limit values, number of measurements, average value, minimum thickness of test piece |

Output Interface |

Can connect external mini printer (optional) |

Electronic Brinell Hardness Tester

Direct Reading Brinell Hardness Tester

Main Function

- Only used to measure Brinell hardness for metallic materials without heat treated such as unquenched steel, cast iron, Non-ferrous metals and soft bearing alloy, etc.

- Automatic loading, load holding timing and unloading when doing measurement.

- Dual core close-loop control for loading and measurement, 16 bit AD and digital output, all above made the equipment with high accuracy and stable measuring and displaying value.

- 100 group testing data storage.

- The indentation can be directly measured through micrometer eyepiece.

- The diameter of the indentation and the value of hardness are displayed on LCD display.

- The test times and results either present or history can be viewed and checked in standby mode.

- This equipment is mainly used in machinery manufacturing, metallurgy, building materials and other area.

- Compliant standards:

a) National Standard: GB / T231.2-2002 "Metal Brinell Hardness Test Part 2: Inspection of Hardness Tester".

b) International Standard: ISO6506.2

c) American Standard: ASTM E-10

Specifications:

Test force |

1839N (187.5kgf), 2452N (250kgf), 7355N (750kgf), 9807N (1000kgf), 28420N (3000kgf) |

Indenter ball diameter |

2.5mm, 5mm, 10mm |

Test force holding time |

6 ~ 99 seconds, can be set |

Measuring hardness range |

8~650HBW |

Maximum test space in vertical direction |

230mm |

Horizontal indenter axis from front wall |

120mm |

Power |

220VAC, 50 ~ 60Hz, 2A |