Controller

The POP-M Industrial PC controller is a pure digital controller. It has a full size I-PC, a connecting box with signal and power amplifier, and several AD and I/O cards. Together with LCD, keyboard and mouse, the operator can use the POP-M to control the actuators performing multi-channel static or dynamic structure or material test.

- Each channel has the capability of double analog input with 16 bit AD resolution, one analog output with 12bit DA resolution, 2 I/O, and one SSI digital signal input.

- The SSI digital input is used by Magnetostrictive Displacement Sensor

- Every channel has 1kHz AD sampling frequency.

- Every channel has 200Hz PID adjusting frequency. It can be set up to 1 kHz depending on the need of the system and the composition of the POP-M..

- The acquired data can be stored in the controller or output by means of LAN or analog output.

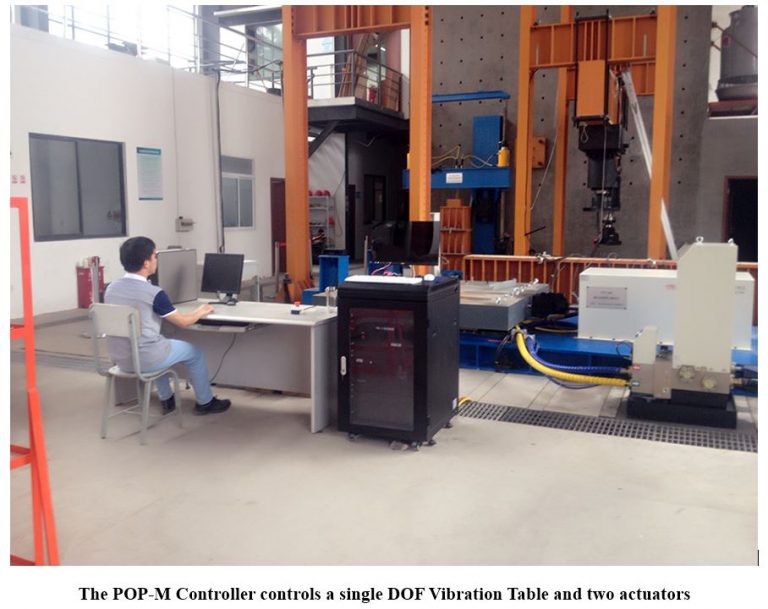

- One POP-M controller can control as much as eight actuators individually and simultaneously to perform complex test.

- Multi sets of POP-M controller can form a control network via LAN to achieve up to 1024 independent actuators controlling to finish a complex structure test.

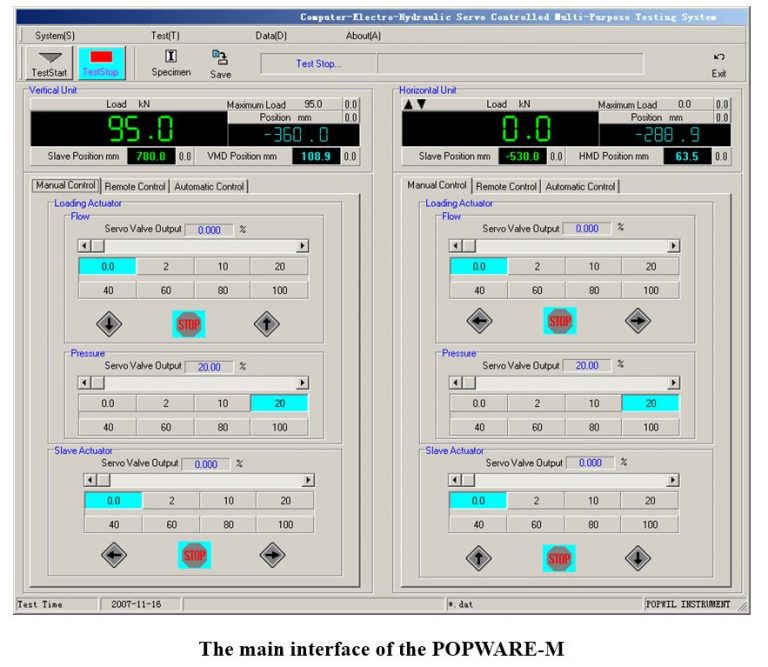

Software

The operating software of the POP-M controller is called POPWARE-M。It was developed by POPWIL in 2004, worked under Windows 98, and the first copy was sold to Tongji University—famous for her Civil Engineering College in China. Since then, the software is under improving continuously. The most recent copy of the POPWARE-M can control as many as 128 actuators separately and simultaneously under Windows 10. The operator can control a test and make data acquisition by simply click the mouse. The most important advantage of the software is that it can be customer originated software. The customer also can make special adjustment of the software such as arrange of the interface or the sequence of a special operation according to their test requirement.

The main interface of the POPWARE-M shows bellow.