The 11200t multi-function joint loading system for large scale structure test is developed by Popwil. The customer is Beijing University of Technology. The system includes a new 7200T electro-hydraulic servo controlled testing equipment and an upgraded existing old 4000T loading device. These two equipments now can work independently to do separate test or working together like one machine to perform the test which needs extra high load. The 7200T testing equipment can be moved into or out of the main frame of the old 4000t loading device through the guide rail transportation system. A POP-M 6 channel controller which is used to control the 7200T loading device can also work as the server of the 11200t joint loading system to control these two loading machine at the same time to realize the joint loading test, so as to achieve the maximum vertical pressure of 11200t and the maximum vertical tension of 2000t.

The plan drawing and main technical specifications are as follows.

The plan drawing of the joint loading system doing joint loading

The plan drawing of the joint loading system doing separate loading

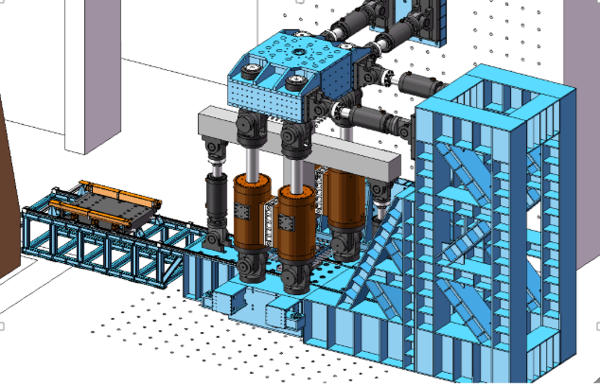

7200T loading device inside of 4000t loader for joint loading

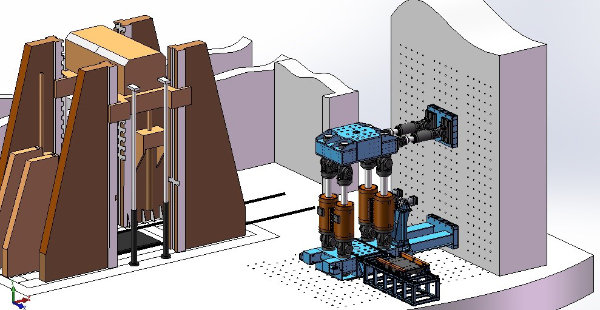

7200T loading devices for independent working

Main Technical Specifications of The Joint Loading System:

1. The 4000t loading equipment has been updated by a new POP-M 4-channel electro-hydraulic servo controller instead of the original STD bus controller, which improves the response speed, control accuracy and stability of the system.

2. Completed the exchange of controller of 4000t loader crossbeam lifting system, using PLC controller to replace the original electric controller, in order to make the crossbeam lifting more stable and reliable.

3. The newly made 7200T loading device adopts POP-M 6 channel electro-hydraulic servo controller, which can not only complete the closed-loop control of 7200T loader, but also work as a server, to control the controller of 4000t loader through the network, and complete the joint synchronous loading of 11200t, greatly improving the loading capacity of the system.

4. The 7200T loading device can moved into or out of the 4000t loading device and it can be fixed in front of the nearby reaction wall for independent use without affecting the normal use of 4000t one.

Technical Specifications of the 7200t Loading Device:

1. The indication accuracy of the test force is ± 1% of the indication;

2. The effective range starts from 250t to 7200t;

3. With full closed-loop control of displacement and load;

4. Equipped with electro-hydraulic servo controlled anti tilt system and deflection control system, which can prevent from front and rear roll and control the angle of left and right deflection;

5. The height of loading specimen: 4.15M --5.15M;

6. The piston in the middle height: 4.65m;

7. The loading space height: 3.75m;

8. The maximum bearing area (plane size) is 1.3m * 2m;

9. The stroke of the actuator is ± 500mm;

10. The maximum loading speed: 5mm / min;

11. Equipped with a specimen delivery system.