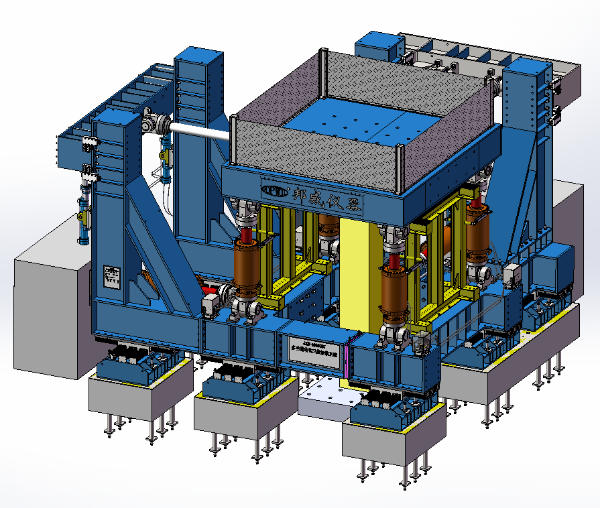

MAST (Multi-Axial Testing System) is a large-scale structure seismic 3D simulation loading system. It is a multi-degree of freedom test system jointly developed by Professor Yan Xiao, a famous scholar in the field of structural anti-seismic researching, and Popwil. The first generation of MAST was completed and put into use in the Civil Engineering College of Hunan University, which mainly realizes the seismic test of plane loading structure with vertical load and horizontal load completely separated. The latest generation of MAST which can apply 3D load and 3D bending moment to perform 6-DOF loading has been built and put into use in Nanjing University of Technology. The design scheme, field test photos and main technical specifications are as follows:

The 3D drawing of MAST

Main Technical Specifications:

- Four 250t vertical loading actuators apply vertical load synchronously;

- Maximum compression load: 1000t, maximum tensile load: 400t

- Maximum horizontal X-direction load: 400t; maximum horizontal Y-direction load: 200t;

- Vertical piston stroke: 600mm

- Horizontal x-direction and Y-direction piston stroke: 800mm;

- Effective range of load: 4% - 100% FS;

- Realize full closed-loop control of displacement and load;

- Test space of conventional configuration (length * width * height, actuator piston in middle position): 2600x1800x5200mm;

- The size of specimen bottom mounting surface: 2600mm * 1800mm;

- The top loading plate part is provided with through-hole for column cap connection, with the maximum area of 2600 * 1800mm; the deformation under the maximum load of the loading plate is not more than 1 / 600.

- Equipped with computer electro-hydraulic servo 8-channel controller POP-M and windows application software POPWARE-M, MAST is specially used for the seismic performance test of typical structural specimen. The software can be customized to realize the function of space track cyclic loading.

- Equipped with hydraulic power station with flow rate of 100L / min.

User: Hunan University, Nanjing University of Technology