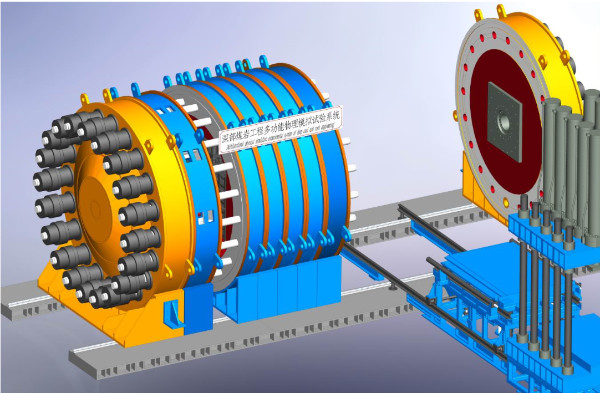

The multi-function physical simulation testing system of deep coal and rock engineering developed by Popwil for the College of Resources and Environment of Chongqing University is mainly used for the laboratory simulation testing research of deep coal and rock engineering under the action of ground stress and gas pressure, such as roadway excavation, support, gas outburst control, etc.

The system consists of a set of cylindrical loading frame composed of multiple circular loading rings together with front and rear end covers. Each loading ring and front and rear covers of the loading frame are fixed together to form a loading chamber by 20 pull rods with prestressed loading device. Inside the loading chamber, 432 20 ton surface loading actuators, which are divided into 11 loading channels, are installed on the rear end cover and cavity, together with the front end cover, to form a 1200 * 1200 * 2000 mm testing space. The surface loading actuators can apply up to 10MPa stress on the specimen in the testing space. As the surface load actuators are grouped by rows and columns, this made it possible to realize the automatic synchronous or asynchronous group step loading. Another important feature of this loading frame is that there are sealing rings between each loading ring and between the loading ring and the front and rear end covers. During the test, gas (usually use cabon dioxide instead of methane for safe reason) can be fullfilled into the closed loading chamber under controllable pressure. The maximum inflation pressure can reach 5MPa. The front cover is provided with drilling holes, through which the drilling machine can drill the specimen. The problems of water and gas outburst or dig chamber support in different depth are simulated and researched by drilling under different surface load and inflation pressure.

The design drawing, site photo and main technical specifications of the system are as follows.

Design drawing of Multi-function Physical Simulation Testing System

Onsite Photo at Chongqing University

Main technical parameters:

1. Loading frame: cylindrical loading frame with seal and prestressed locking between rings. The prestressed pull rod ensures the reliability of sealing;

2. Surface load actuators: 432 surface load electro-hydraulic servo actuators are divided into 11 groups, which can realize closed-loop steped and layered loading;

3. Test chamber size: 1200 * 1200 * 2000mm;

4. Load simulation capability:

1) maximum surface stress 10MPa;

2) maximum gas pressure 5MPa;

5. Controller and software:

The windows application software popware-m controls the pop-m multi-channel controller with 11 closed-loop control capabilities, which can realize the simulation of the earth stress of 432 surface load actuators with a maximum of 10MPa and the inflation pressure of 5MPa, and complete the simulation research of mine support, gas and Water Outburst under the deep and complex geological conditions.

6. Auxiliary device:

1) The system is equipped with a model drill, which can be fixed on the front cover and drill the sample in the cavity through the reserved holes.

2) The system is equipped with a test making device, which can compress the sample in advance when making the sample, so as to prevent excessive sample deformation after being sent to the closed chamber.