PWS-J Series Electro-hydraulic Servo Controlled Dynamic-static Universal Testing Machine for Structure Test

With its unique long base plate and testing attachments such as bending support seats, low friction double layer sliding plates and ball joint etc., POPWIL PWS-J series testing machine is specially designed for both dynamic and static structure test.

The most important features of this kind of testing machine are that it can do dynamic or fatigue test for structure test at the frequency range from 0—50Hz beside normal static structure test. There are threaded holes at designed spacing distance in order to fix the attachments and specimen on the long base plate. A typical PWS-J testing machine is composed of 4 parts.

- A main frame and testing attachments.

- A dynamic servo actuator with double rods, servo valve, inside installed displacement sensor and a load cell.

- A hydraulic power station with hydraulic pipe and distributor

- The controller and software.

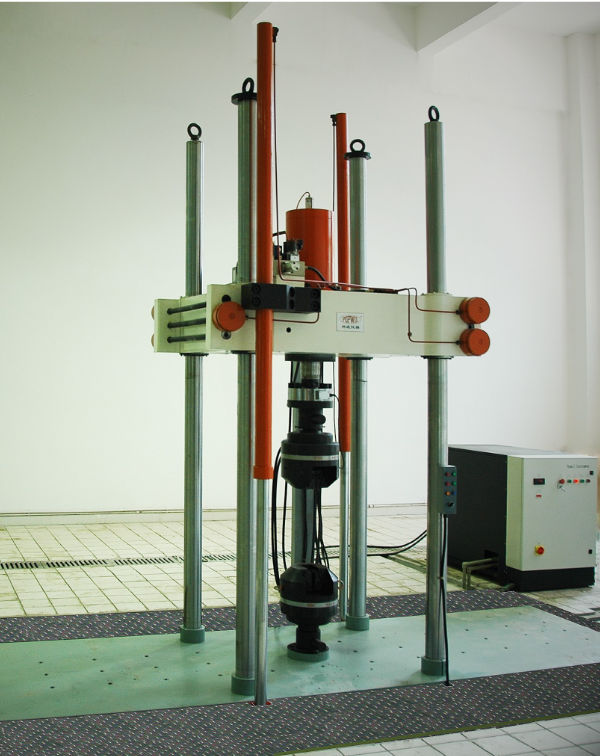

The follow picture is a PWS-500J computer servo controlled electro-hydraulic Dynamic-static universal testing machine.

The picture of a PWS-500J computer servo controlled electro-hydraulic Dynamic-static universal testing machine

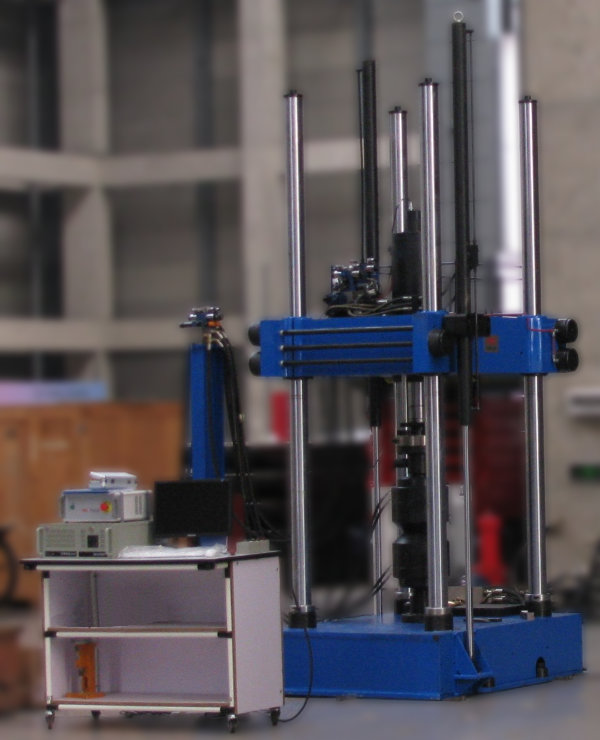

The picture of a PWS-1000J computer servo controlled electro-hydraulic Dynamic-static universal testing machine

Specifications:

Type |

PWS-200J |

PWS-500J |

PWS-1000J |

PWS-2000J |

PWS-3000J |

Max.Load(kN) |

200 |

500 |

1000 |

2000 |

3000 |

Load Accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

Load Validity Range |

4%-100%FS |

4%-100%FS |

4%-100%FS |

4%-100%FS |

4%-100%FS |

Working Frequency (Hz) |

0-50Hz |

0-30Hz |

0-30Hz |

0-20Hz |

0-10Hz |

Max. Stroke(mm) |

±75 |

±100 |

±100 |

±100 |

±100 |

Max. Working Space(height mm) |

600 |

1000 |

1500 |

1500 |

1500 |

Column Center Spacing (mm) |

700*600 |

1000*700 |

1000*700 |

1100*900 |

1100*900 |

Base Plate Size(L*W mm) |

2500*850 |

3500*1300 |

4000*1300 |

4000*1400 |

4000*1400 |

Hydraulic Nominal Flow Rate (L/min) |

50 |

100 |

200 |

400 |

600 |

Power Supply (kW) |

25 |

50 |

100 |

200 |

300 |

Shape Size of Main Frame(L*W*H)mm |

2500*1122*3550 |

3500*1740*4100 |

4000*1740*4790 |

4000*1850*4850 |

4000*1850*5000 |

Shape Size of Hydraulic Power Station(L*W*H)mm |

780*1900*1500 |

1000*2020*1710 |

1150*2360*1770 |

3300*1750*1950 |

4400*1750*1950 |

Main Frame Construction |

Four Column Main Frame; Upper Installed Actuator |

Four Column Main Frame; Upper Installed Actuator |

Four Column Main Frame; Upper Installed Actuator |

Four Column Main Frame; Upper Installed Actuator |

Four Column Main Frame; Upper Installed Actuator |

Net Weight(kg) |

4200 |

11000 |

13000 |

18000 |

20000 |

Working Noise(dB) |

82 |

85 |

85 |

90 |

90 |

PWS Series Electro-hydraulic Servo Controlled Dynamic-static Universal Testing Machine for Material Test

A picture of PWS-500 electro-hydraulic servo controlled Dynamic-static universal testing machine

The PWS series Dynamic-static Universal Testing Machine is used for both dynamic and static material test.

The differences between PWS-J series and PWS series are that the PWS-J series has a long base plate and structure testing attachments but no specimen clamping heads, and the PWS series has a pair of clamping head and a relative short base plate.

The PWS series testing machine can be used to do ordinary static material test, but its most important feature is that it can do dynamic or fatigue material test at the frequency range from 0—100Hz. So that it can be used in some special dynamic tests such as Crack Growth Rate, Fracture Toughness and other fatigue properties in normal or abnormal temperature conditions according to the standards of material test such as ASTM, ISO etc. A typical PWS testing machine has 4 parts.

1) A main frame and testing attachments.

2) A dynamic servo actuator with double rods, servo valve, inside installed displacement sensor and a load cell.

3) A hydraulic power station with hydraulic pipe and distributor

4) A controller and software.

The follow picture is a PWS-500 computer servo controlled electro-hydraulic Dynamic-static universal testing machine.

Specifications:

Type |

PWS-50 |

PWS-100 |

PWS-200 |

PWS-500 |

PWS-1000 |

Max. Load(kN) |

50 |

100 |

200 |

500 |

1000 |

Load Accuracy |

±1% |

±1% |

±1% |

±1% |

±1% |

Load Validity Range |

4%-100%FS |

4%-100%FS |

4%-100%FS |

4%-100%FS |

4%-100%FS |

Working Frequency (Hz) |

0-100Hz |

0-100Hz |

0-50Hz |

0-50Hz |

0-30Hz |

Max. Stroke(mm) |

±50 |

±75 |

±75 |

±100 |

±100 |

Max. Testing Space(mm) |

500 |

500 |

600 |

600 |

700 |

Thickness of Flat Specimen (mm ) |

0-18 |

0-21 |

0-26 |

0-30 |

0-45 |

Diameter of Round Specimen(mm ) |

φ5-φ20 |

φ5-φ25 |

φ6-φ30 |

φ10-φ40 |

φ10-φ60 |

Column Center Spacing (mm) |

600 |

600 |

715 |

1000*700 |

1000*700 |

Working Table Size(mm) |

1200*1300 |

1200*1300 |

|||

Nominal Flow Rat of Hydraulic Power Station (L/min) |

20 |

50 |

50 |

100 |

200 |

Power Supply (kW) |

13 |

25 |

25 |

50 |

100 |

Shape Size of Main Frame(L*W*H)mm |

890*620*2600 |

890*620*2690 |

1030*770*3100 |

1200*1740*4000 |

1200*1740*4200 |

Shape Size of Hydraulic Power Station(L*W*H)mm |

700*1675*1385 |

780*1900*1500 |

780*1900*1500 |

1000*2020*1710 |

1150*2360*1770 |

Main Frame Construction |

Dual Column; Under Table Installed Actuator |

Dual Column; Under Table Installed Actuator |

Dual Column; Under Table Installed Actuator |

Four Column Main Frame; Upper Installed Actuator |

Four Column Main Frame; Upper Installed Actuator |

Net Weight(kg) |

580 |

620 |

890 |

8000 |

10000 |

Working Noise(dB) |

78 |

82 |

82 |

85 |

90 |