Popwil joined together with The College of Information science and Electronic Engineering of Zhejiang University to invest six million to build a new public experimental platform, named Interdisciplinary Motion Dynamics Simulation Platform, and focused on R&D in the area of Multi-degree-of-freedom seismic and space attitude simulation and control.

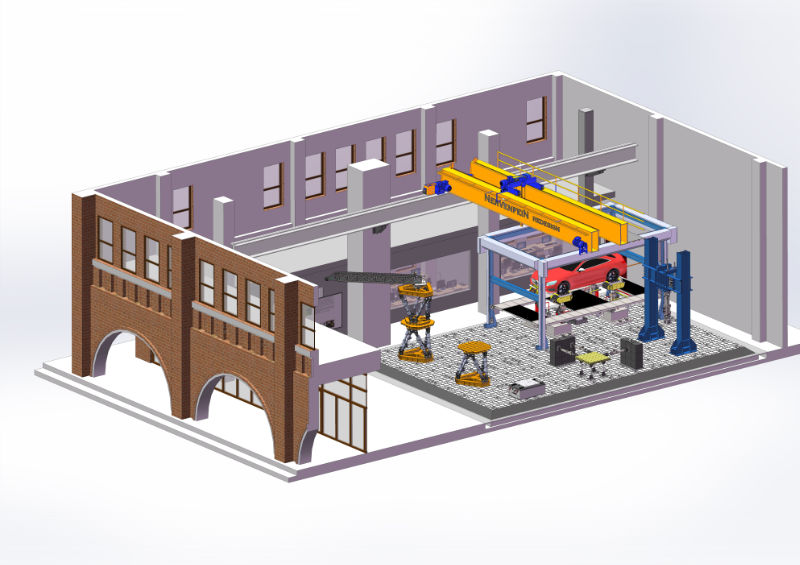

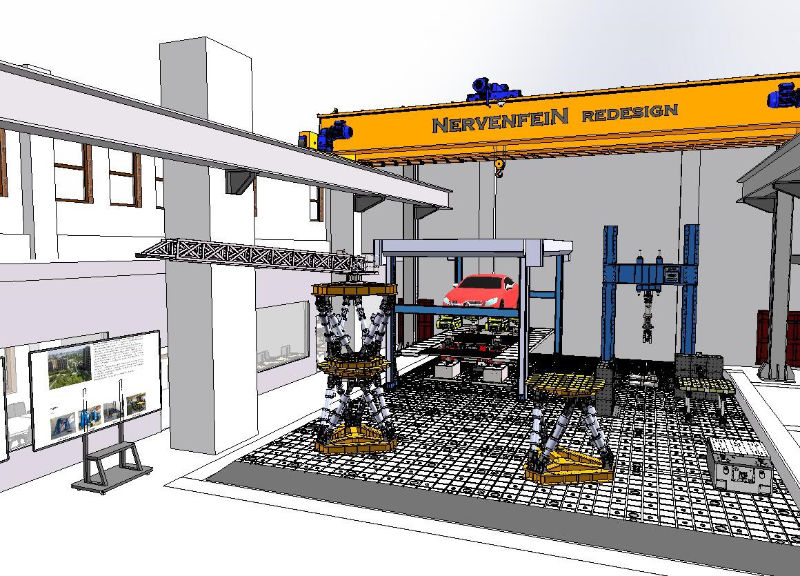

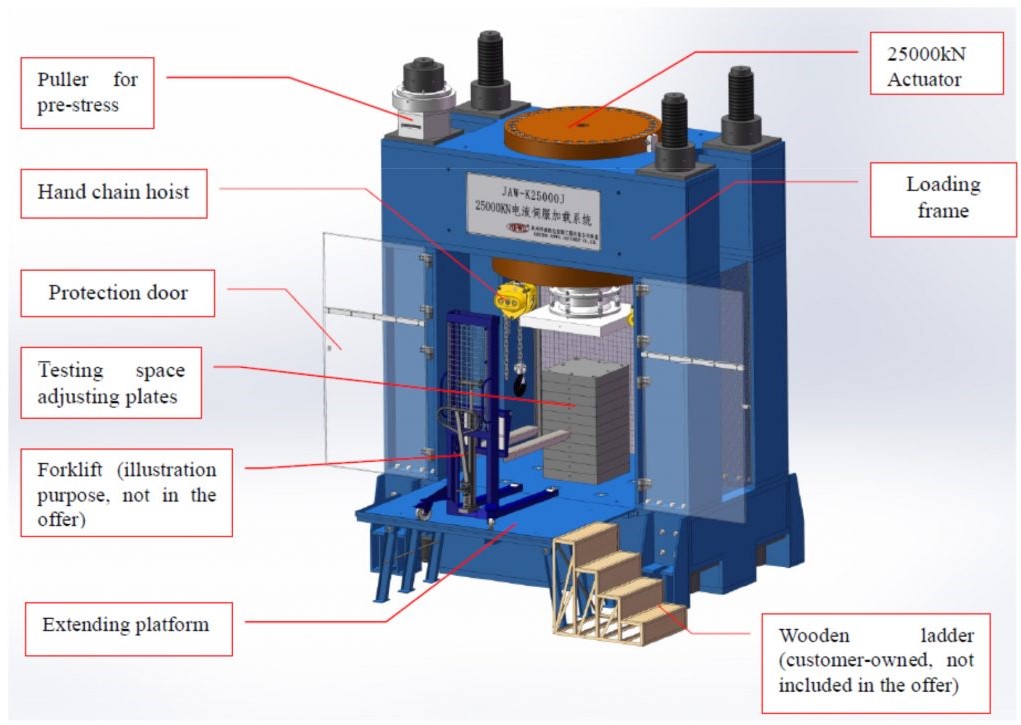

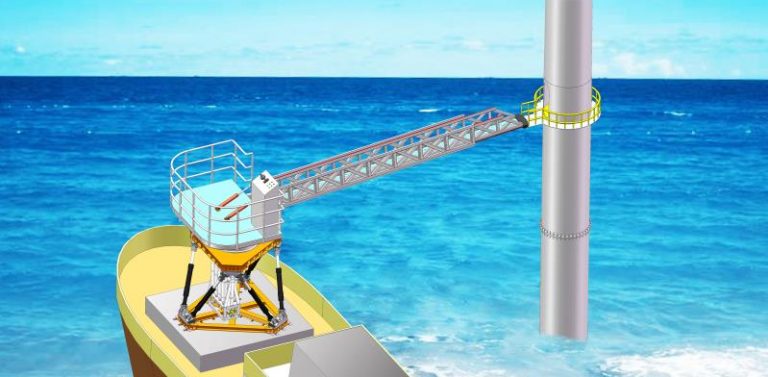

The new laboratory is located in the beautiful Haining campus of Zhejiang University, and has floor area of 500 square meters. The laboratory will build a high response 6 degrees of freedom Stewart platform based on a 5G network-based integrated data acquisition system. The platform is also equipped with silent hydraulic power system and other related equipment. The short-term goal of the laboratory is to develop a new generation of ultra-high-speed POP-M controllers with closed-loop control frequency exceeding 4 kHz with new network-based control software. The middle term goal is to do R&D on associated technology and products in civil engineering test and quality control, motor vehicle road simulating and seismic simulating platform, space or sea state motion and attitude simulating platform, and other related fields.

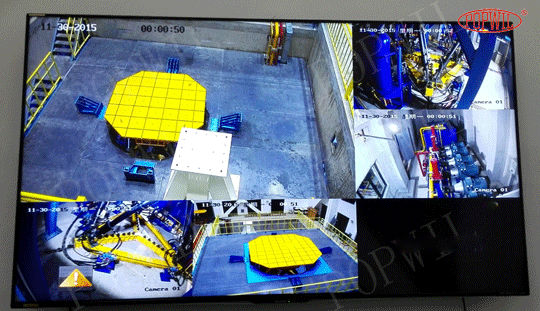

Appearance of the completed laboratory